-

Formwork

ISOSPORT has developed an innovative composite panel for the formwork industry to ensure high demands such as long product life, uniform mechanic rigidity, and stiffness are met. The principle is based on sandwich design. A light, pressure-resistant core material is inserted between two carrying top layers: polypropylene combined with aluminium or glass fibers.

For inquiries, consultation regarding applications and orders, please contact our sales partner Alkus AG. -

Surface films for formwork panels

We offer a special surface film for finishing wooden formwork panels. This film consists of woodfiber-reinforced polypropylene with fleece laminated atop, allowing for bonding to various massive wooden constructions by applying phenol, melamine or other adhesives used in the lumber industry.

Our surface films are utilized for concrete formwork panels and production panels for concrete blocks. For further information, please visit ISOKON. -

Flood protection

LAMINAEX AL PP is also utilized in flood protection panels exposed to high surface pressure. Thanks to aluminium reinforcements, this product offers optimal rigidity and high bending strength while being low in weight.

Since the panel does not absorb any water, it is optimally suited for effective use in flood protection systems. In combination with mounting systems, support systems and interconnection systems manufactured by customers themselves, we provide mobile or partially mobile flood defense lines in lengths according to customer specifications.

Panels can be employed for protection of building openings, such as doors and windows, of any desired size through attached sealing systems.

Type of panel

LAMINAEX AL PP polypropylene foam with aluminium reinforcements and PP coating.

Thickness of panel: 13 to 27mm

Property profile- Water resistance

In contrast to regular wooden panels, LAMINAEX sandwich panels do not absorb any water, thus there is no swelling or shrinkage and product life of the sandwich panel is significantly increased. - UV resistance

LAMINAEX panels are weather-resistant and can be employed in every type of climate.

UV rays do not adversely affect the material properties of LAMINAEX, ensuring long durability. - Low weight

The low weight of LAMINAEX panels facilitates transportation and logistics. - Clean solution

The utilization of LAMINAEX is a clean solution in the truest sense of the word – handling and cleaning are easy and environmentally sustainable. At the end of their product life, the panels can be stored indefinitely. - Dimensional stability

LAMINAEX is dimensionally stable and flexible, suitable for application in every climate, weather-resistant and provides uniform load-bearing capacity.

- Water resistance

-

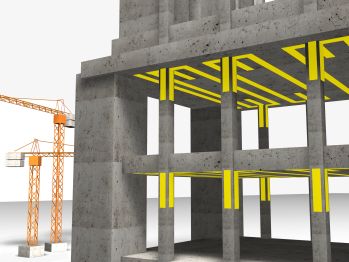

Building and structure reinforcement

For this application, ISOSPORT offers cured fiber-reinforced epoxy composites with high-strength carbon, basalt or glass fibers based on innovative technologies. These pre-fabricated slats are utilized in bridge building, building construction and infrastructure construction and in historic buildings as well as in earthquake protection of building complexes.

The fiber composite slats can be bonded to the surface of a building or integrated into pre-fabricated slots. This combination of materials selection and reinforcement methods ensures durable, ecologically sustainable measures for restructuring and construction of buildings made of concrete and wood while requiring limited amounts of raw materials and at the same time reducing resources required in the construction industry.

In this field of application, besides glass fibers, we mainly use carbon fibers as reinforcing fibers for our ISOGLASS products.

Thanks to a special pre-tensioning system of roving fibers utilized in the manufacturing process, optimal alignment of carbon fibers is ensured, thus safeguarding a linear arrangement of the e-module in the finished product (slat). Depending on customer specifications, we offer slat types with various strength values.

This completely cured epoxy laminate (CFK slat) features special advantages such as:- Significantly higher e-module than all other fiber composites

- Low coefficient of expansion

- Outstanding fatigue behavior

- High resistance against chemicals

- High corrosion resistance

- Frost resistance and resistance against de-icing salt

Areas of application for building reinforcements

- Slats bonded to the surface of the building or brickwork

- Slats bonded to the surface of the building with end anchoring devices, also suitable for designs with several layers

- Slats bonded into slots in upright alignment

- Wrapping of columns and pillars

Downloads:

- ISOGLASS Folder.pdf .PDF, 1.32 MB

- CaseStudy - CFRP Laminates.pdf .PDF, 227.58 kB

-

Playgrounds

In the field of playground construction, the properties of LAMINAEX panels are optimally suited for playground applications as riding surface for skater ramps and as panels for boards that constitute the boundaries of sports facilities such as ice hockey rinks.

We also deliver LAMINAEX panels in colors according to customer specifications by laminating the functional surface films of panels during the manufacturing process. Panels can further be delivered with grained structures that add additional grip for riding skateboards on such surfaces. In this type of application, mainly glass-fiber reinforced sandwich panels that feature high impact strength and bending strength are processed. Further reinforcement through the integration of glass fiber mats also ensures sufficient rigidity for utilization in boards of ice hockey rinks.

The material’s UV resistance and its outstanding water-repellent properties make it ideal for durable applications in the field of playground construction.

Type of panel:

LAMINAEX GM PP with surface film mounted on both sides

Panel thickness 10 mmProperty profile

- Water resistance

In contrast to regular wooden panels, LAMINAEX sandwich panels do not absorb any water, thus there is no swelling or shrinkage and product life of the sandwich panel is significantly increased. - Surface

LAMINAEX is suitable for basically ever type of surface design, whether an application requires special anti-slip surfaces for skateboarding or colorful designs of boards of hockey rinks. - UV resistance

LAMINAEX panels are weather-resistant and can be employed in every type of climate.

UV rays do not adversely affect the material properties of LAMINAEX, ensuring long durability.

- Water resistance

Your contact:

Günter Erhardt

+43 2682 703 254

g.erhardt@isosport.com