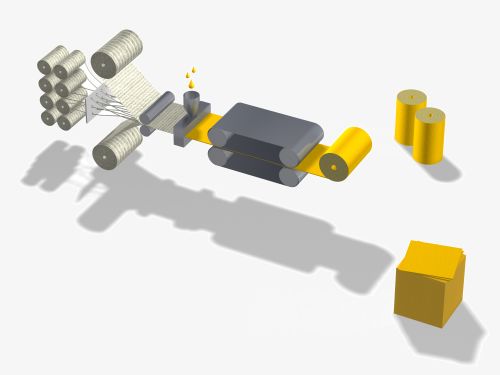

Advantages of the pultrusion process are high process speeds and flexibility in the production of flat and planar products. In the scope of the process, the fiber bundles (rovings) that consist of several thousand individual filaments are regularly distributed into the cross-section desired via a perforated plate. Subsequently the rovings are impregnated with a resin curing compound (matrix) in the resin impregnating station. The object is to net every single filament with the matrix because this is to only way to ensure the optimal mechanical properties of the fabric composites.

A stripper tool removes surplus matrix and is the preliminary stage to thickness calibration. After the impregnation of every individual filament is intensified through targeted temperature and pressure application and the raw thickness of the unidirectional fiber composite is adjusted before final curing of the resin.

Our experience has shown that the adhesive strength of adhesive bonds is on a very high level regardless of surface structures of fiber composites. Still we are able to increase surfaces through subsequent light sanding, respectively brushing to optimize the quality of adhesive bonds even further. Please bear in mind that this may lead to fiber damage on the surface that may impact mechanical properties of the fiber composites.

We assemble the products according to customer specifications and, depending on thickness, deliver them on rolls or in units.

Your contact:

Manuel Ressler

+43 2682 703 560

m.ressler@isosport.com