We offer two types of welding methods for plastic (maximum length of welding seam: 4000mm):

Your contact:

Günter Erhardt+43 2682 703 254

Butt-welding or mirror-welding

Sheets are aligned along a heating element; the resulting resin layers are permanently connected without an adhesive layer.

Examples of applications:

LAMINAEX AL EP or LAMINAEX GM PP Sheets

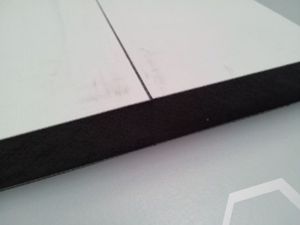

In LaminaeX sheets, the reinforcing layer aluminium is set back in the joint area and is not connected.

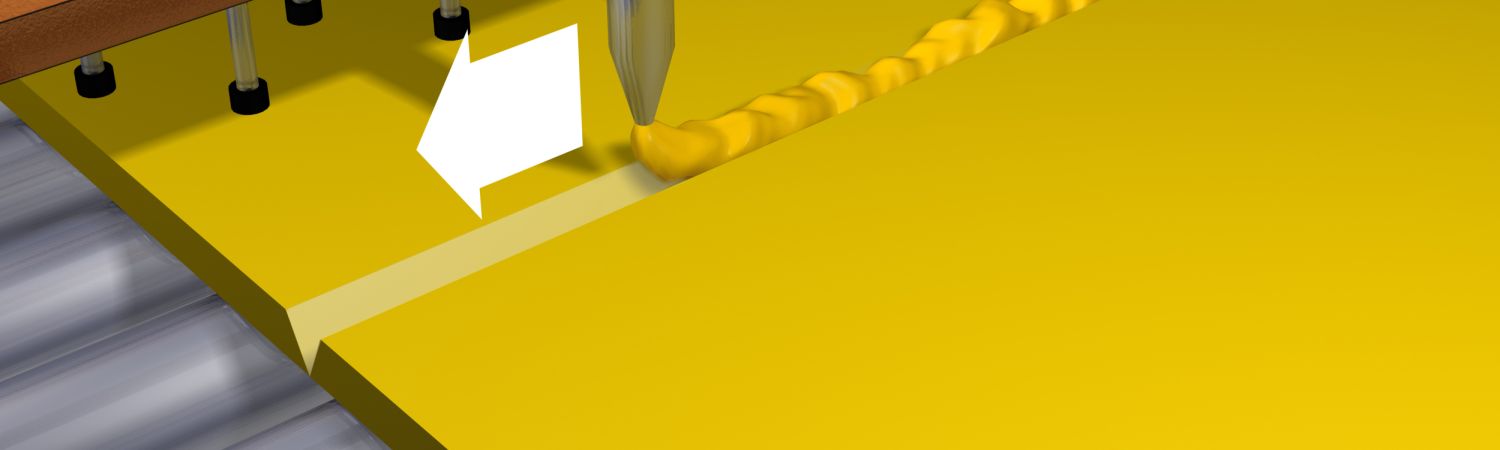

Seam technology based on extrusion

By employing this type of welding technology, we provide our customers with oversized, large-format sheets that even feature almost seamless surfaces.

The special attribute of this welding method is that on one side of the sheet, the welding seam is only visibly as butt joint and the sheet is still welded across the entire cross-section. There is no need for machining the seam, the surface of the sheet remains in its untouched original condition.

The specially chamfered (prepared as V-shape) edges of the sheets are connected and joint with a welding seam with an extrusion-welding machine.

Application example:

LaminaeX AL PPsheets