In this process, a stack of fiberglass pads is continually impregnated with PUR foam In this process (ISOCORE), a stack of fiberglass pads is continually impregnated with PUR foam, turning them into blocks with a width up to 600mm and a thickness between 25-60mm.

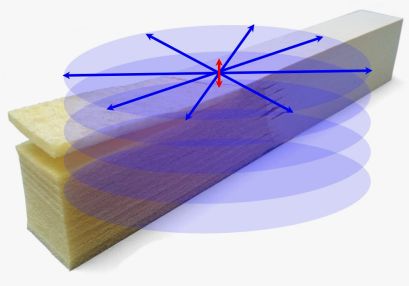

This leads to a very high fiber orientation parallel to the fleece layers, while orientation remains accordingly low vertically, thus providing the desired anisotropic property profile.

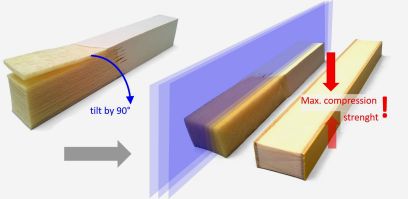

Through the targeted use and optimal alignment of the fibers, compressive strength is maximized.

The production of larger blocks through bonding of several layers is available upon customer request. If such blocks are cut into battens, they provide for are larger-format modules with very high compressive strength.

Your contact:

Manuel Ressler+43 2682 703 560