Biobased polyamides - the sustainable alternative

Biobased polyamides, such as Polyamide 11 (short: PA11), have been used for several decades in various markets due to their durability and outstanding technical properties. Biobased polyamides are derived from castor oil among others, which comes from the seeds of the castor plant (Ricinus communis).

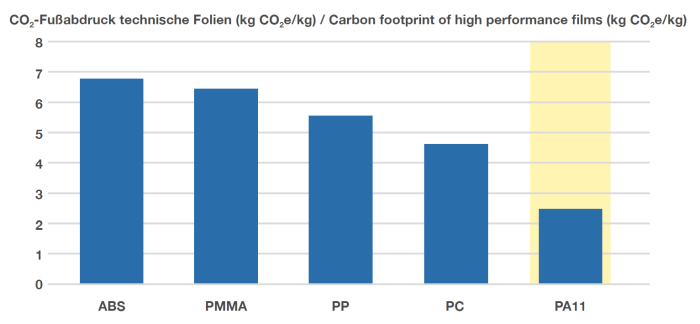

This makes them a sustainable material with a low carbon footprint (see diagram). Biobased polyamides can be easily recycled, helping to further reduce a company’s ecological footprint.

Advantages

Additionally to their natural origin, biobased polyamides are considered high-performance plastics, mainly due to their numerous advantageous properties compared to other materials:

High chemical resistance

Biobased polyamides are resistant to a variety of chemicals (including oils, fats, and various solvents).

Low density

Biobased polyamides are approximately 20% lighter than polycarbonate. This makes them a valuable raw material for applications where weight plays an important role.

High scratch and impact resistance

Both at room temperature and as well as at very low temperatures, biobased polyamides impress with their high impact resistance and high scratch resistance compared to other polymers.

Low moisture absorption

Due to their low moisture absorption, biobased polyamides can be used in a variety of wet environments. Additionally, alcohol, acids, and esters are only minimally absorbed by biobased polyamides.

Film-Portfolio

Available thickness: 30-750 μm

Width: up to 750 mm

Colors and structures on request.