Most of our films are manufactured by means of flat die extrusion from the following plastics:

-

PA - Polyamide

The all-rounder. This is our area of expertise. We specialize in the processing of premium grades of polyamides such as PA11, PA12, PA1010 and amorphous or microcrystalline polyamides.

These films feature high resistance against wear, abrasion and chemicals and high heat deflection temperatures as well as good mechanical resistance. In addition, they offer outstanding transparency (especially amorphus and microcrystalline grades), high surface brilliance and excellent UV resistance!

We also offer a vast range of embossed foils in this quality featuring unique and surprising optical depth effects (Opto 4D, lenticular films).

All polyamide films can be decorated by utilizing conventional printing methods, however, thermotransfer printing is especially suited.

Applications: FIM (Film Insert Molding), Ski and snowboard surfaces, decor carriers, paint replacement films, advertising and design applications (especially embossed foils)

-

PBT - Polybutylenterephthalate

Films made from PBT also boast high resistance against chemicals and abrasion. In contrast to polyamide films PBT is characterized by much higher heat deflection properties although PBT films are only available in opaque coloring while still offering high surface sheen and brilliance. UV resistance is below that of PA.

As standard these films are supplied with fleece backing to improve adhesion with substrates. Surface embossing is available upon request. Like PA, PBT also meets all the requirements for decoration using thermotransfer printing.

Applications: Decor carriers, Ski and snowboard surfaces, water sports, advertising and design applications (especially embossed foils)

-

TPU and TPU blends – thermoplastic polyurethane

As one of the most important elastomers, TPU covers a vast range of properties: its durability, flexibility, transparency and high resistance against wear are one of a kind.

Special materials combinations with other polymers provide these films with a balanced profile of properties.

In this class of materials, we also offer films based on the Permaskin® compound by BASF. It is extremely durable, weather-resistant and offers exceptional color consistency and resistance against chemicals.Special consideration was also placed on high formability (vacuum thermoforming). The film aligns itself exactly with the structures of the substrate and is a perfect alternative to conventional painting processes.

Unlike PVC, this film does not contain any plasticizers, ensuring that materials stay soft and pliable over a long period of time.

Applications: Ski and snowboard surfaces, decor carriers, high-grade surface finishing of three-dimensional substrates made of wood or metal, indoors as well as outdoors, such as of furniture, doors, windows or garage doors.

-

ABS and ABS blends – Acrylonitrile butadiene styrene

Based on our sidewalls for skis we continue driving forward in the development of special film grades made of ABS.

As amorphous raw material, ABS offers exceptional impact strength, dimensional stability and heat deflection properties. ABS is available in different colors and is easily thermo-formed. We also process different blends such as PA/ABS, TPU/ABS, etc. Depending on grade, films are available with outstanding surface brilliance.

Applications: deep drawing applications, FIM (Film Insert Molding), Ski and Board Components

-

PE – Polyethylene PE-X – Cross-linked polyethylene

Based on manufacturing of ski bases, the focus is on HDPE films with very high molecular weights, ensuring outstanding wear and sliding properties and high heat deflection levels. With cross-linked PE, these properties are reinforced further and almost reach the level of sintered skived films.

Applications: Sliding elements in logistics or machine engineering with very high tribological properties, Ski and snowboard running bases

-

PP-Polypropylene

PP offers an excellent price-performance ratio. Low density, high resistance against chemicals, high rigidity and great thermoformability are among the further advantages of these film materials for a comprehensive range of applications. Besides standard qualities (homopolymers and copolymers), we are also specialized in responding to the unique needs of our customers (such as electric conductivity, heavy layer films, etc.)

Scratch resistance of PP can be increased significantly by embossed structures!

Applications: deep drawing applications of all kinds, FIM (Film Insert Molding), electrically detectable applications, sound absorption

-

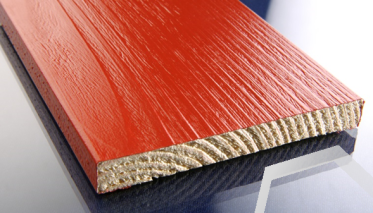

Fabric composites (fabric coating, extrusion coating, coating)

Besides plain monofilms or co-extruded films made of plastic, we also offer composite films with different fleeces, fabrics or other films.

These composites are produced by extrusion laminating or coating. The composite material can be used on one side, both sides or as core layer.This way, properties are managed in a targeted fashion (decrease in elongation behavior, increased rigidity, improved bonding bridge for adhesive bonds, purposes of decoration, etc.)

Applications: hose shrouds, ski surfaces, decorative films, etc.

-

Other materials, special films

The materials outlined above are the base for our expansive range of standard products of flat die extrusion films.

On top we have extensive experience with many other thermoplastics such as TPE, PET, PMMA, EVA, ionomers, fiber-reinforced plastics etc. Basically there are no limits!Past customer inquiries have shown that in most cases only individualized product formulations with special additives have yielded the sought-after product properties. In order to implement these wishes in series production as well, we are equipped to compound these specialist materials and to manufacture the respective films in-house.

With multi-layer films (co-extrusion), it is possible to combine various properties of different plastics in one film (i.e. very high scratch resistance on one side and high bondability on the other side). Currently up to three different materials can be combined in this manner!

If you are looking for a film with special properties and/or a complex structure, be sure to contact us! We are looking forward to assisting you and to providing optimal solutions for your needs based on an attractive price-performance Ratio.

-

PMMA – Polymethylmetacrylat

PMMA is a highly transparent material with excellent UV stability. PMMA is easily thermoformed. PMMA films provides a very high scratch resistance and surface hardness. Compared with PA or PC the heat resistance and the level of mechanical properties are lower.

Unique design effects and optical properties, will be achieved by using targeted embossed structures.

Applications: thermoforming applications, FIM (Film Insert Moulding)

-

PC – Polycarbonat

Films made of PC provides very good optical properties such as high transmission and very low haze. PC is easily thermo-formed and characterized by high impact strength and heat resistance.

The amorphous nature causes low chemical resistance of PC.

The scratch resistance can be significantly increased by the targeted use of embossed structures.

Applications: Thermoforming applications, FIM (Film Insert Molding)

Downloads:

- CaseStudy - Embossed film for coffee machine.pdf .PDF, 558.24 kB